Samsung’s Galaxy S9 Plus Costs Just $379 to Build

Posted by AZEEM ULLAH

Every year, with each new and flashy flagship, comes a post which reveals how much it actually costs to produce that phone. The latest in this series is the Galaxy S9+, the bigger variant of Samsung’s recent flagship duo.

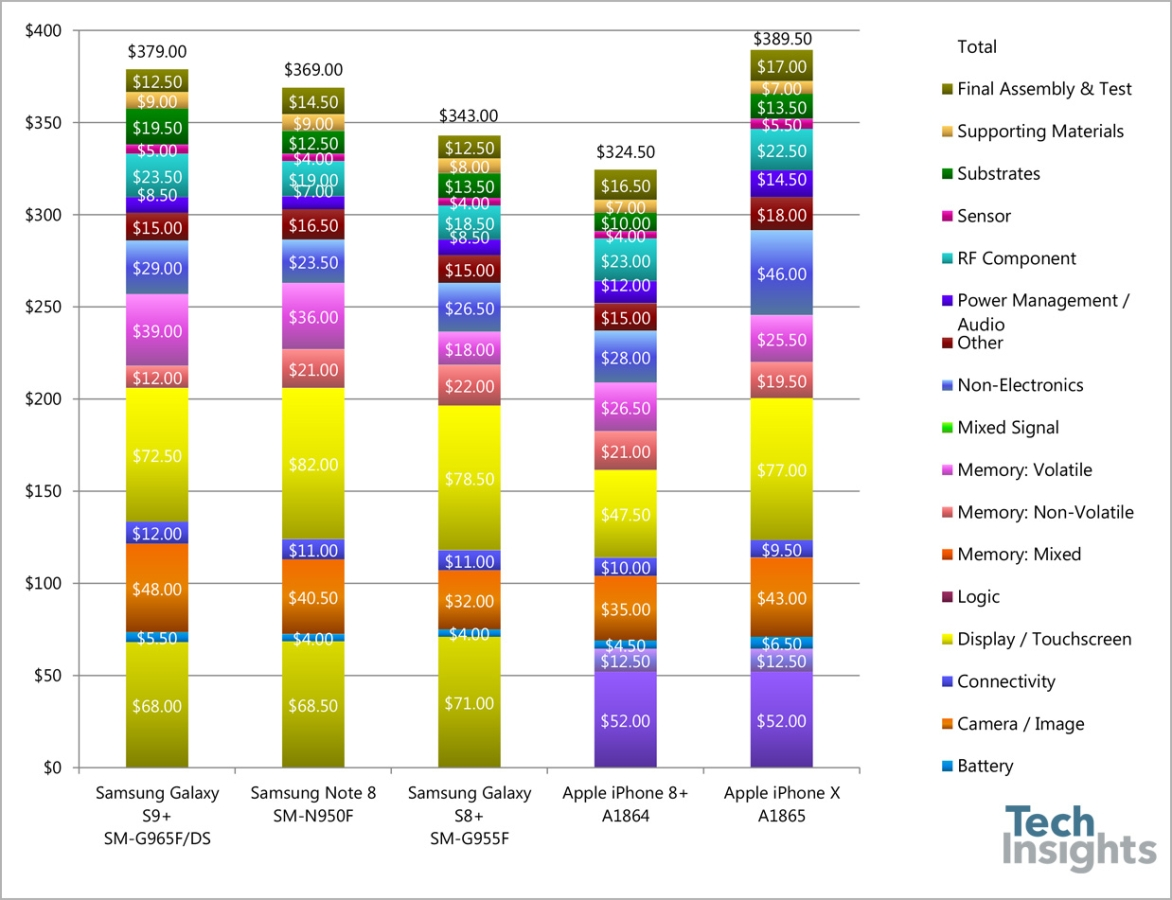

The phone apparently costs $379 to manufacture, according to a TechInsights report, which makes it the most expensive phone to build for Samsung. It takes the crown from the Note 8, which was $10 cheaper. The S9+ does cost less than the iPhone X, which costs $389.50 (though it retails for a much higher $999).

Cost Breakdown

The most expensive component in the S9+ is its 6.2″ curved Super AMOLED panel on the front, which costs $72.5 apiece. It cost $82 on the Note 8, being slightly larger in size. The next is the new Exynos 8910 chipset, which costs $68.

ALSO READ

Samsung Officially Launches the S9 and S9+ in Pakistan

The new dual-camera setup on the back is next, costing $48, followed by the memory (volatile) which costs $39. The non-electronic components cost $29. The battery is among the cheapest components at just $5.5.

All of these components combine to form the final cost of $379, which is actually less than half the final total of almost $850, which is what Samsung charges for the Galaxy S9+.

Cost Factors

Of course, the final price also has to account for the external cost factors, most-notably after-sales services, supply chain & logistics, and most importantly, research and development.

Samsung is the third largest spender in terms of R&D, spending $12.7 billion in the domain, $2.7 billion more than Apple. Obviously, companies with smaller margins like Xiaomi spend a lot less on R&D compared to Samsung, which decreases the overall price a bit.

The post Samsung’s Galaxy S9 Plus Costs Just $379 to Build appeared first on .